FRP Advantages & Benefits

Fiberglass Reinforced Plastic manufactured by Saudi Pultrusion Industries offer several advantages against aluminum, wood and steel.

Manufacturing Material Comparisons

| SPI pultrusions | Extruded Aluminium | Wood | Steel | |

| *Wood expands due to moisture absorption.

**Wood is also susceptible to insects and mold. |

||||

| Strength to Weight | High | Medium | Low | High |

| Thermal Conductivity | Low | High | Low | High |

| Expansion And Contraction | Medium | High | Low* | Medium |

| Corrosion and / or Chemical Resistance | High | Medium | Medium** | Low |

| Electrical Conductivity | Low | High | Low | High |

Pultruded Product vs Aluminium

- Super Insulation Qualities: 600 – 800 times more thermally insulative.

- Dimensionally Stable: 3/1 the expansion and contraction

- Strength: 50% more tensile strength

- Lighter: 20% – 30% less weight

Pultruded Product vs Wood

- Lower Maintenance: less upkeep than wood products

- Strength Protrusions: have a much higher strength to weight ratio

- No Insect Problem: FRP profiles are not a food source for termites, wood ants, etc.

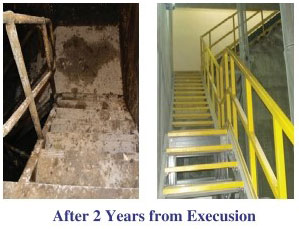

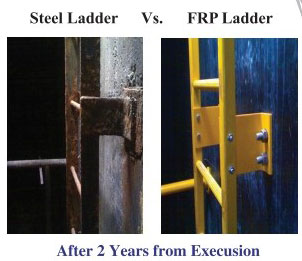

Pultruded Product vs Steel

- Corrosion Resistant: pultrusions will not oxidise or corrode

- Much Lighter: 75% less weight

- Better Insulation Qualities: 150 – 200 times more thermally insulative

- Strength: up to 30% more tensile strength than mild steel

Feature Characteristics Of FRP

- Chemical and Corrosion Resistance The use of premium grade resins containing UV inhibitors and an outer reinforcing continuous strand mat topped by a non-glass surfacing tissue, optimum protection against corrosion and weathering can be achieved.

- It resists a wide range of aggressive acids, salts, alkalis and other chemical environment which can have disastrous effect on metallic grating systems.

- High strength to weight ratio superior strength to weight ratio to steel or aluminum systems. It is highly resistance to fatigue, creep or permanent deformation.

- Lightweight and manageable the pultruded fiberglass used has a specific gravity of one – fourth that of steel and two-thirds that of aluminum which considerably simplifies installation and handling.

- Non-Conductive fiberglass can be used safely in electrical work areas. Special support conditions to prevent electrolytic is not required.

- Transparent to radio frequency pultruded fiberglass do not interfere with electromagnetic and radio frequency transmission. It can be safely applied in towers and other structures used in the transmission of such signals.

Stand Resin System

- Standard polyester (ISO) resin system the standard polyester resin system refers to a non-flame retardant isophetalic polyester resin system . This resin system is manufactured in olive green and incorporates ultraviolet inhibitors. Polyester resins exhibit good corrosion resistance, good electrical properties, low thermal conductivity and external mechanical properties .

- Flame retardant polyester (ISOFR) resin system this resin exhibits the same characteristics as the standard polyester resin system with a flame spread rating of 25 or less when less when tested in accordance to ASTM E-84. The flame retardant resin is manufactured in gray and yellow.

- Flame retardant viny1 ester (VEFR) resin system this resin system is manufactured from viny1 ester resin which exhibit higher strength, improved strength and stiffness retention at elevated temperatures, and improved corrosion resistance. This system also meets a maximum flame spread rating of 25 and produced in beige and yellow color.